Thank you for taking the time to read our first edition of Conversations@Tangible for 2024. Our theme this year is ‘Ideas, Perseverance and Attention to Detail’.

Ideas, Perseverance and Attention to Detail

We want to celebrate people and brands that identify, articulate, and deliver their offers by seemingly leaving no stone unturned in the quest to create exceptional products, services, and experiences for their customers.

When we’re talking about Ideas, Perseverance and Attention to Detail, it may be the celebration of the engineering behind Dyson’s products or the craft that Disney puts into storytelling or a beautifully crafted logo that articulates the ambition of the business.

The key to building exceptional brands may be a combination of many circumstances but we would like to suggest it’s a blend of brilliant ideas, dogged perseverance, and an obsessive attention to detail (with a scoop of luck and timing). We can’t always explain it, but we know when brands have gone the extra mile to deliver.

Dyson – Ideas, Perseverance and Attention to Detail

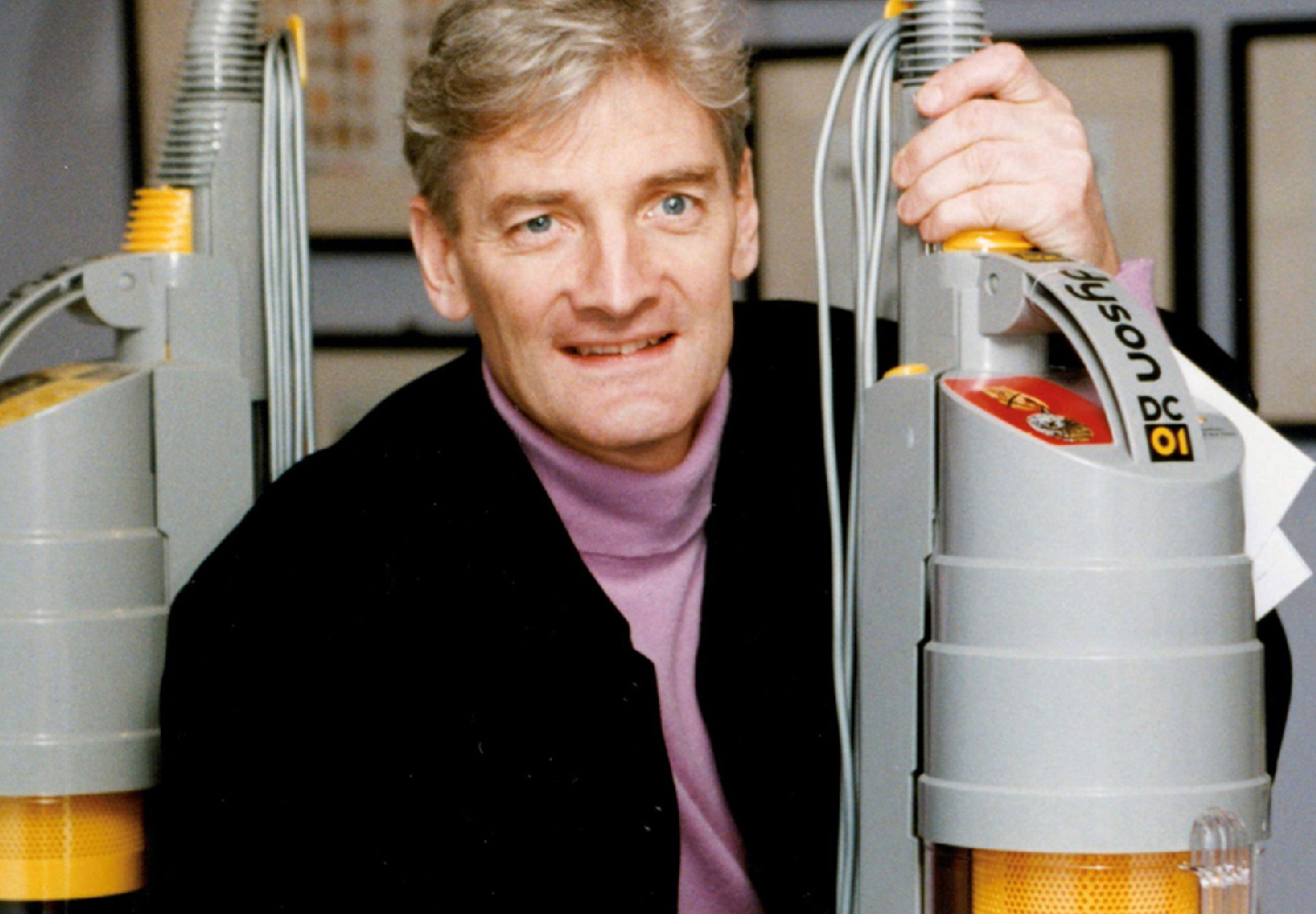

The story of James Dyson is a daisy chain of brilliant ideas woven with the steel wire of perseverance. It’s interesting that both James Dyson and Phil Knight (Nike) were long-distance runners. James Dyson attributes his determination to his long-distance running.

Before the first bagless vacuum cleaner, while studying at the Royal College of Art (RCA), James Dyson helped design and build an amphibious high speed landing craft with the entrepreneur, Jeremy Fry. It was during this time that James learnt to design and engineer a product from the ground up. After graduating from RCA, James then helped with the sales of the ‘SeaTruck’ from Rotork Controls Ltd.

With the ‘SeaTruck’ success in his toolbox, James Dyson’s next idea came while renovating his farmhouse in the Cotswolds. He was having issues with traditional wheelbarrows, as they were unstable when fully loaded and put high pressure through the central tyre. His solution was the ‘Ballbarrow’, a single piece moulded plastic bucket and a ball for the front wheel. The success was immediate and ‘Ballbarrow’ quickly took half of the UK wheelbarrow market.

James Dyson clearly has a creative mind, but this is tempered with an engineer’s attention to detail and a long-distance runner’s perseverance, which has proved a formidable combination.

‘Dyson’ is synonymous with, the cyclonic vacuum cleaner and this was James Dyson’s next big idea. Its genesis originated in the late 1970’s after James Dyson saw a 30-foot-high conical centrifuge used in a sawmill to remove dust from the air. He believed the technology could be adapted for vacuum cleaners to improve their performance by removing the collection bags. At that time all household vacuum cleaners used collection bags which lost suction as the bags became clogged.

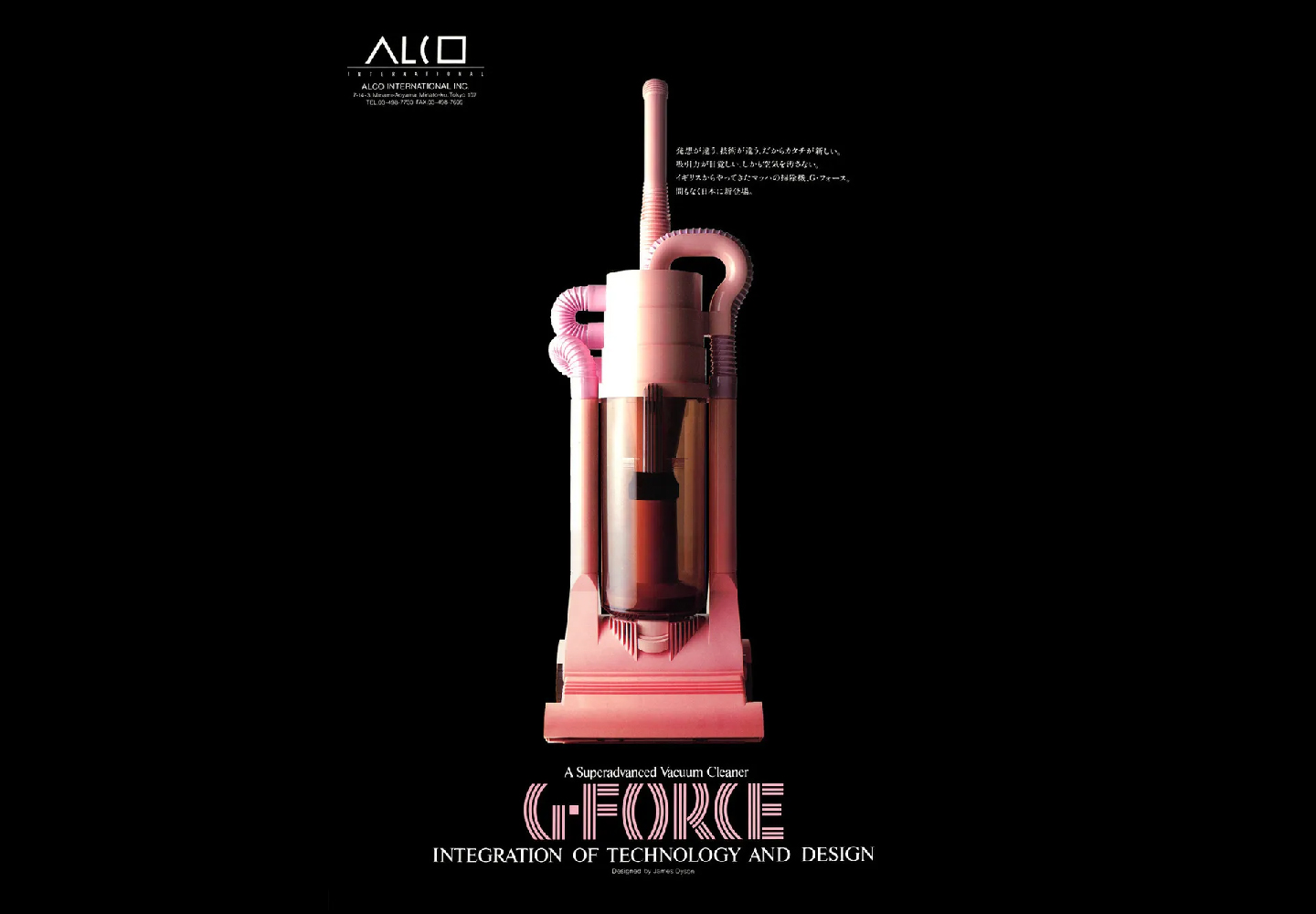

This is where perseverance comes in again as it took James five years and about 5,127 prototypes for the “G-Force” cleaner to be born in 1983. During this time, he was partly supported by his wife’s teacher’s salary. The next hurdle was manufacturing and distribution, as no one in the UK would handle his product (as Dyson disturbed the market for replacement dust bags). So, Dyson launched the G-Force in Japan through a manufacturing license agreement with a company called ‘Apex’. After this initial success Dyson realised that if he wanted to take his innovations to market, he needed to steer the ship. So, together with a bank loan and his life savings ‘Dyson Appliances Limited’ was founded in 1991. James then doubled down by setting up his own manufacturing company, ‘Dyson Ltd’ in 1993.

The 1990s was a story of growth for Dyson and particularly the Dual Cyclone model. Within two years, it was outselling Hoover and began capturing market share rapidly. Other models followed, which generally shrank in size and grew in desirability. Growth also brought the opportunity for Dyson to focus on his passions, ideas, innovation, and engineering. With the appointment of Martin McCourt as the Group CEO, James Dyson focused on growing the product offer. Let’s briefly summarise where his company cast its creative eye.

Washing Machines

With the insight that washing machines take 2 hours to deliver the results of 15 minutes of hand washing, Dyson ventured into washing machines. The result was the ContraRotator, which mimicked hand washing with its two drums rotating in opposite directions. Technically it was a great product, more energy efficient and could tackle larger loads. Unfortunately, at double the cost of competitors’, it failed to capture the market and become a commercial success.

Hand Dryers

Launched in 2006, Dyson’s Airblade Hand Dryer has helped Dyson grow within the commercial appliance sector. By challenging existing products, the Airblade uses Dyson’s digital motor to power a stream of air at rapid speed to dry the hands within 10-14 seconds. It is accredited as the first-ever hygienic hand dryer, using a HEPA filter to eliminate bacteria from the air, and in the process costs less to run than conventional hand dryers.

Bladeless Fans

As first glance the bladeless fan looks like another brilliant idea off the Dyson conveyer belt of brilliant ideas. Who wouldn’t want a fan that you can put your hands or head into? Actually, the concept for a bladeless fan was created by Toshiba in 1981 but it was beautifully designed and popularised by Dyson. The Air Multiplier was launched in 2009 and was included in Time’s 50 Best Inventions of that year.

Lighting

Jake Dyson, the son of James Dyson, is also working for the family business in the lighting sector. The opportunity in this sector is to address problems caused by poor lighting, such as eyestrain, headaches, and decreased productivity, all while enhancing the ambiance with optimal lighting. The lighting division started in 2004 and has moved from Halogen to LED light sources. While lighting may not have received the commercial success of other divisions, Jake says if there’s anything he learned from his father, it’s to “never give up”.

Hair Dryers

32 years after the G-Force, Dyson moved into hair care. In 2016 the Supersonic hairdryer launched to rave reviews, then came the Airwrap, an all-in-one styler and finally a straightener; the Corrale. With all these products the mission was clear, to create products for ‘every hair type, every style with less damage’. It took 10 years and £100 million but Dyson is now the category leader with over 6,000 engineers, scientists, and stylists working globally to drive their mission forward.

Another key focus area is the attention to detail from product design to the marketing and communications of Dyson products.

Dyson’s product designs can be compared with Apple’s, with their sleek and simple outer appearance that belies the sophisticated technology concealed within. The naming of their products captures both the category and technology incorporated within the product. Who knew what a neodymium magnet was before the cyclonic vacuum cleaner came along. Or that is spins at 104,000 times a minute, which is faster than a Formula 1 car (a great comparison).

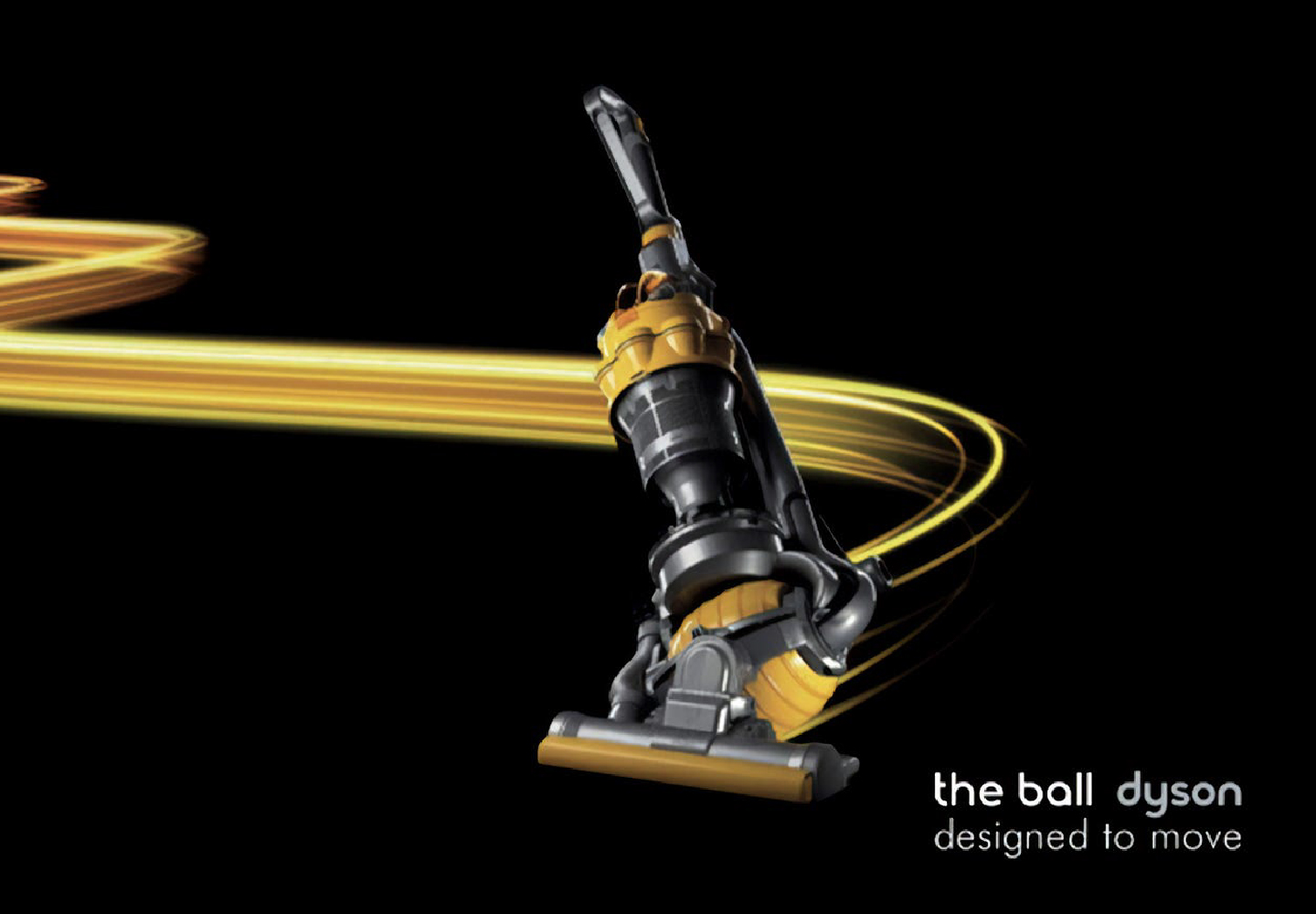

From a marketing and communications point of view, when you see Dyson’s ads, websites, or retail outlets, it’s clear that the products (or the engineering behind the products) are the focus for the Dyson brand. It’s not about lifestyle, convenience, or value, it’s a celebration of the innovation, engineering excellence and attention to detail.

Looking back on James Dyson’s journey, it is hard not to be impressed by his achievements and hope his story can inspire the next generation of entrepreneurs driven by their internal curiosity to ask; ‘why not?’ And a determination to meet with triumph and disaster and treat those two imposters just the same.

Sources:

https://www.dyson.ie/james-dyson

https://www.cascade.app/studies/dyson-strategy-study

https://en.wikipedia.org/wiki/James_Dyson

https://support.dyson.com.sg/fans

Share this article [addthis tool="addthis_inline_share_toolbox"]